Project Case|Taicang Seedling System

Release time:

2023-07-11 17:34

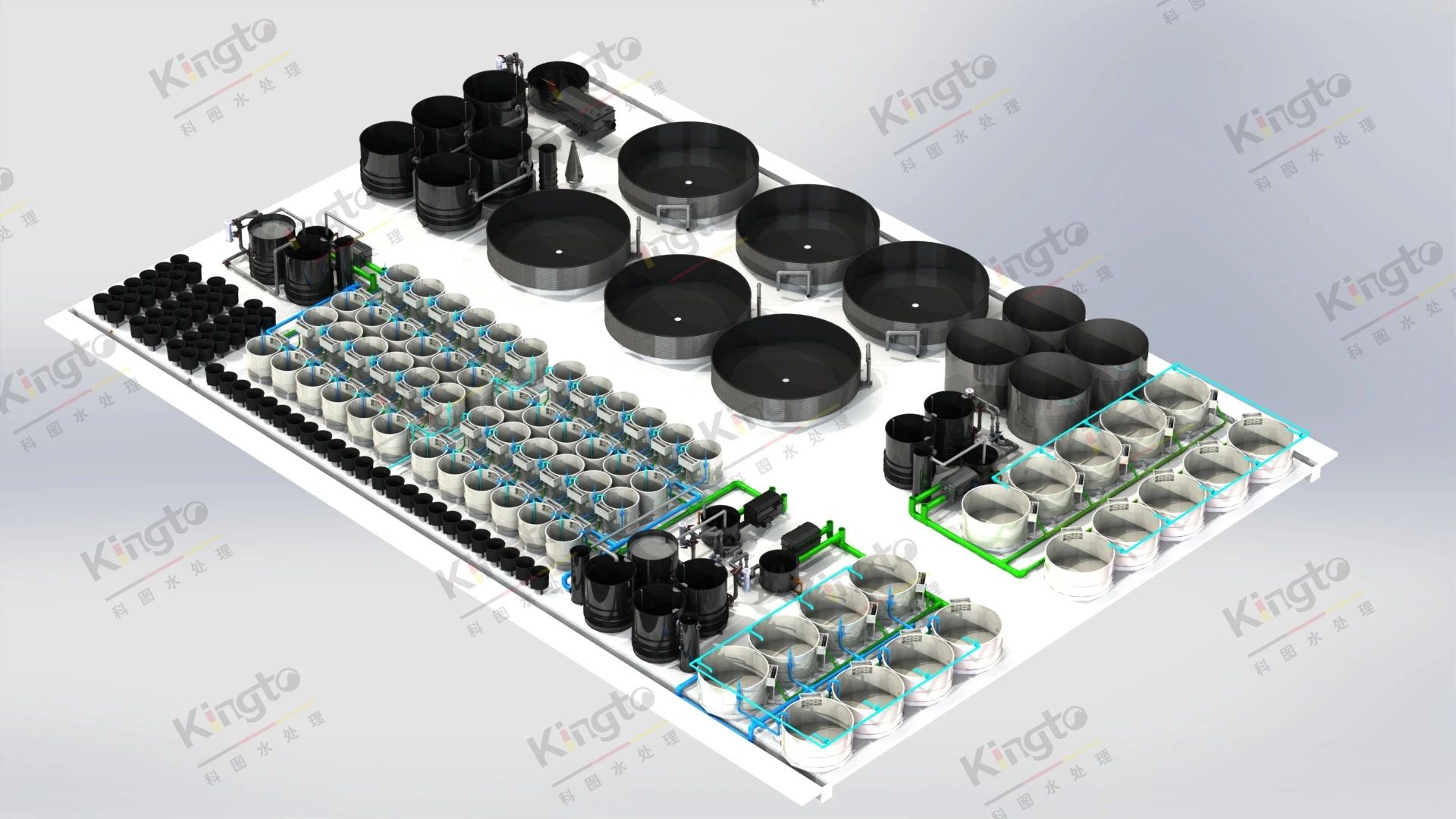

The seedling raising system jointly developed by Suzhou Kingto Water Treatment Equipment Co., Ltd., Aikeman (Taicang) Agricultural Technology Co., Ltd., Tianjin Jiangze Technology Co., Ltd., and Zhejiang University is currently under construction in the Taicang Seedling Base.

The whole system includes fish pond, microfiltration machine, pump pond, circulation pump, ultraviolet sterilizer, fixed biological bed (FBBR), mobile biological bed (MBBR), medium pressure oxygenator (MHO) and air energy heat pump.

This nursery system is suitable for almost all seawater and freshwater fishes, such as California bass, mandarin fish, snakehead, yellow catfish and channel catfish, and can stabilize the survival rate of fry. It can better control and regulate the breeding water body, saving heating costs and labor costs.

This system is another seedling raising system project of Kingto Water Treatment after the completion of Aikeman Shanghai seedling raising system. Dr. Li Dongchun, general manager of Aikeman, fully affirmed Kingto products. The product design, materials and workmanship are all higher than the industry level and standard.

● Nurturing process

Taking California perch as an example, the seedling raising process of this system is divided into three-level systems.

● Level 1 system

The first level of breeding is water splash to 5000 tails/catties. The breeding pond is equipped with an adjustable water distribution system, which can flexibly control the water flow speed in the breeding pond, effectively collect sewage, avoid impact on fry, and greatly save manual sewage suction cost. The backwater area uses a large-throughput double-insert structural design, which facilitates the replacement and cleaning of the filter screen, and at the same time reduces the water flow velocity in the drainage area to prevent the fish fry from being adsorbed to death. Since the first level of seedling breeding has high water quality requirements, we strictly follow the circulating water treatment process to ensure the safety of the aquaculture water through physical filtration, biological filtration, UV sterilization, temperature adjustment, aeration device and IoT control system.

● Second and third level systems

The water treatment process of the second-level and third-level aquaculture is basically the same as that of the first level. From the perspective of cost control and raising breeding density. The second level of breeding uses a circular culture pond with a diameter of 3.5 meters. The fry are raised from 5,000 to 1,000 fish/catties, and the final breeding biomass density is 5 kg per cubic water body. The third level of breeding uses a circular pond with a diameter of 8 meters. The fry are raised from 1,000 to 200 fish/catties, and the final breeding biomass density is 15 kg per cubic water body.

● The tertiary system is suitable for adult fish

This system is suitable for breeding California bass to adult size, and the breeding density can reach 50-60 kg/m3.